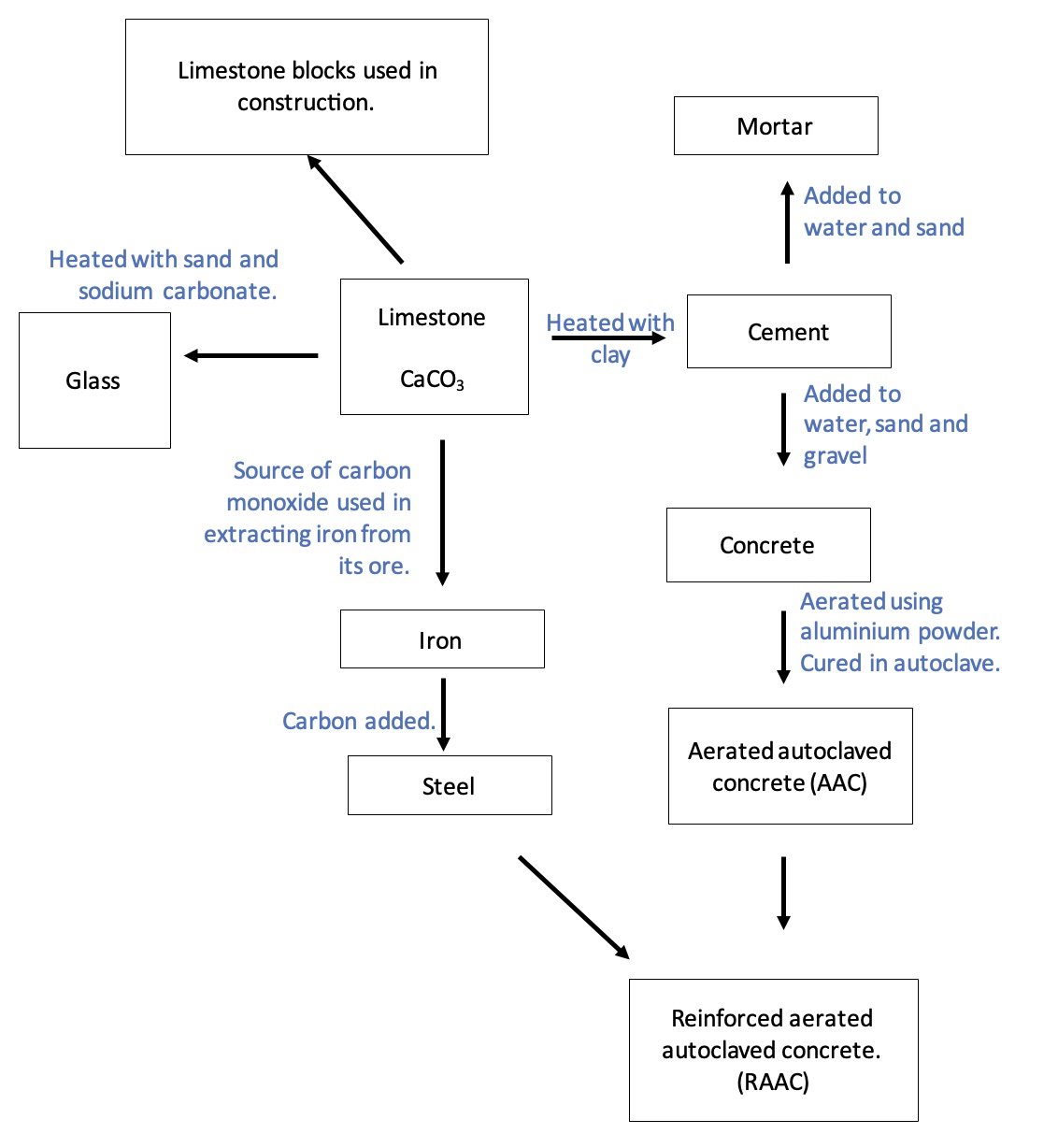

Figure 2. An overview of the use of limestone in common building materials.

Taking the broad definition that concrete is a mixture of a paste and aggregates [1](pieces of hard, inert material), then some of the earliest recorded concrete structures date back to 7000BC and a form of concrete was widely used by the Romans[2] (including in the construction of the Pantheon Dome).

Even modern concrete can be traced back to the work of John Smeaton in the 18th century.[3] Smeaton, who is the first person to describe themselves as a civil engineer, developed a type of concrete known as hydraulic lime when building the Eddystone lighthouse. The material he developed was a huge improvement over previous wooden structures as it was resistant to both fire and damage by the wind and waves.

An English bricklayer (Joseph Aspdin), then improved the material made by Smeaton with the invention of Portland cement in 1824. Named after the Portland rock it resembled, Aspdin made his cement by burning powered limestone with clay to make a substance that would harden when mixed with water. [4] Aspdin’s work came at a time when there was renewed interest in finding building materials other than wood or stone, with the Industrial Revolution creating ever increasing demand for fire resistant buildings that were relatively inexpensive to construct. [5]

However, though concrete was cheaper to use as a building material than blocks of stone it still had a comparatively low tensile strength and would fail after relatively little tension was applied. This problem was overcome by François Hennebique in 1892, who pioneered reinforcing concrete with steel rods.[6]

The end of the 19th century also saw various engineers and architects experiment with aerated concrete; using first carbon dioxide and then aluminium powder and calcium hydroxide to make a porous material that performed better under freeze-thaw conditions.[7]

In the 1920s, this new, aerated form of concrete became the research subject of a Swedish assistant professor – Axel Eriksson.[8] Eriksson knew that aerated concrete would have better insulating properties than conventional building materials, giving it a valuable advantage at a time when the Swedish government implemented stricter standards for housing construction to deal with the energy shortage after World War 1. Eriksson also found a way to speed up the curing process; the process by which the loss of moisture in newly made concrete is prevented to improve durability. [9] Eriksson achieved this using an autoclave – thus producing aerated autoclaved concrete (AAC).

Then, in 1935, a competitor to Eriksson began manufacturing AAC panels with reinforced elements, producing an early version of reinforced aerated autoclaved concrete (RAAC)[10]

So, by the post-war construction boom from the 1940s onwards, there was a cheap building material that could be rapidly manufactured into panels that could then be easily installed in roofs, floors, and walls.

How could this possibly be a bad idea?

Figure 3. Rugby Cement works

Well, one issue with RAAC comes from its porous nature. Over time, water can penetrate RAAC and corrode the reinforcing element within the panel. Although this can happen with conventional reinforced concrete, with conventional reinforced concrete the expansion of reinforcing bar (as it corrodes) will typically cause the face of the concrete panel to fall off and expose the reinforcing bar. Thus, with conventional reinforced concrete there are usually visible warning signs of a panel that is soon to fail. However, with RAAC, the expanding reinforcing bar is expanding into a material that contains so much empty space due to aeration that there are often no external signs – meaning panels can collapse with no warning.[11]

Bizarrely, the potential risks associated with RAAC have been well documented for decades as the material is considered to have a maximum life expectancy of 30 years and the Standing Committee on Structural Safety (SCOSS) has been reporting on the dangers of RAAC since the 1990s. One high profile case of a roof made of RAAC collapsing occurred in 2018 in Kent, although as the roof collapsed at the weekend there were no casualties[12].

Figure 4. Royal & Derngate Theatre – one of the many buildings that contain RAAC

So, why has it taken the government so long to take decisive action on RAAC? Perhaps we can never be certain but I’m guessing the considerable costs associated with the widespread replacement of key structural elements of numerous public buildings was a major factor, although that still does not explain why the government finally did act in autumn this year. However, I wonder if another factor played a part in the reluctance to try to modify buildings constructed using RAAC – that the concrete panels would have to be opened up to properly examine the damage to the reinforcing bar and many of these panels from the late 20th century could contain asbestos? This leads us to the next entry in the history of bad ideas… the use of asbestos in buildings.

Photographs taken by the wonderful Chrissy Osborne https://chrissy.lgbt/

[1] https://www.cement.org/cement-concrete

[2] https://ancientengrtech.wisc.edu/roman-concrete/#:~:text=The%20Ancient%20Romans%20used%20their,is%20a%20common%20tourist%20attraction.

[3] https://www.mylearning.org/stories/originating-in-leeds/130

[4] https://www.mylearning.org/stories/originating-in-leeds/122

[5] https://heritagecalling.com/2022/09/22/a-brief-history-of-reinforced-concrete-buildings-in-england/#:~:text=But%20it%20was%20the%20idea,commercially%20successful%20and%20widely%20used.

[6] https://www.jpconcrete.co.uk/francois-hennebique-a-pioneer-of-reinforced-concrete/

[7] https://www.designingbuildings.co.uk/wiki/Autoclaved_aerated_concrete

[8] https://news.xella.com/company/100-years-of-autoclaved-aerated-concrete-how-an-idea-revolutionized-construction#:~:text=1924%20was%20also%20the%20year,easier%20and%20faster%20to%20process.

[9] https://www.concrete.org.uk/fingertips-nuggets.asp?cmd=display&id=393

[10] https://www.aircrete.com/aircrete-news/history-of-autoclaved-aerated-concrete-2/

[11] https://www.youtube.com/watch?v=O4wOH5g_yzQ

[12] https://www.theguardian.com/commentisfree/2023/sep/02/observer-view-on-school-closures-warnings-over-concrete-years-ago

Bad idea 2: reinforced aerated autoclaved concrete (RAAC)

When doing research for this post I was surprised to learn that both concrete and the problems associated with RAAC had a much longer history than I ever realised.

Concrete is one of a number of industrially important materials for which calcium carbonate (CaCO3) in the form of limestone is a key raw material.